eluder87

New member

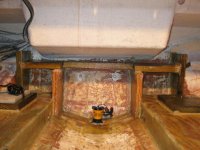

Hi, I'm new to this forum and this is my 1st post. I've found some really good info about transom repair here and wanted to ask something. I pulled my Eluder from Texas to Florida. I noticed after getting home a large crack on my gel coat where the motor mounts. (see pic) I had a transom saver on the boat through out the trip but there were parts of I-10 that were pretty rough. I think that the way the motor was tilted up, the center of gravity of the motor was on the boat side of the transom and the bouncing caused the transom to crack. I tightened up the bolts and tried calking the crack but when I backed it into the water I could see water trickling through the bolt holes. I decided not to launch the boat and repair the transom. I've owned the boat since 1994 and put in a new floor in 1999. The hull is solid.

My question is should I try removing the cap or cutting it about 3 feet from the back?

I started drilling out the rivets on the back end but the more I think about cutting the cap the more I cringe. I hate to molest the cap which is in very good shape. How much more difficult is it to slide the whole cap forward? I'm worried about the steering cables (and others). Are most of the wires and cables attached to the cap? Will these be able to slide forward with the cap?

If I do cut the cap how difficult is it to try and make it look like it was never cut? Will vibrations cause the repaired cut crack eventually?

Thanks,

desperate Eluder

Hi,

Hi,

My question is should I try removing the cap or cutting it about 3 feet from the back?

I started drilling out the rivets on the back end but the more I think about cutting the cap the more I cringe. I hate to molest the cap which is in very good shape. How much more difficult is it to slide the whole cap forward? I'm worried about the steering cables (and others). Are most of the wires and cables attached to the cap? Will these be able to slide forward with the cap?

If I do cut the cap how difficult is it to try and make it look like it was never cut? Will vibrations cause the repaired cut crack eventually?

Thanks,

desperate Eluder

Hi,

Hi,