-

Welcome to the Checkmate Community Forums forums.

» Interact with over 10,000 Checkmate Fanatics from around the world!

You are currently viewing our boards as a guest which gives you limited access to view most discussions, articles and access to our other FREE features.

By joining our free community you will be able to:

» Post topics and messages

» Post and view photos

» Communicate privately with other members

» Access our extensive gallery of old Checkmate brochures located in our Media Gallery

» Browse the various pictures in our Checkmate photo gallery

Registration is fast, simple and absolutely free so please, join our community today!

If you have any problems with the registration process or your account login, please contact support by clicking here or by using the"contact us" link at the bottom of the page.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ran my Verado 400r

- Thread starter Hayabusa

- Start date

Hayabusa

Well-known member

Awesome

It almost looks like the aluminum thickness of your reinforcement is thicker than the aluminum on the jackplate and was wondering if you had any concerns about the jackplate strength? I am still using the CMC jackplate from when the 300 was on there and noticed it was rated at 350HP. Not sure if that was because there were only 350HP out at that time or if it's truly rated for 350HP and should I be concerned...

I suppose this also raises the question on how jackplates are rated and if the predominate factor for jackplate ratings is HP, weight, or some combination. The weights are similar and therefore torque is probably the factor?

No real concern with the jack plate, Bob's make one for the 400 & V8's which is identical in material thickness but wider to accommodate the Verado foot print, I think the CMC was rated to 350 cause it was the biggest hp motor out there at the time & have no doubt it will hold & work the 400 with out an issue, yes I believe the combo of weight & torque are considered, torque more so as it has to get the boat on plane & hold that bow right were you want it & jumping a wave? Lots of stress (torque)

JUPITER PULSARE

Well-known member

The Merc is going on tomorrow plus a couple of aluminum trim pieces then a full systems check & we're off to the races, yeah

Get her done! We're planning a lock park to Clewiston run on sunday the 24th!

Hayabusa

Well-known member

Looks nice. Looks like you will have the plate all the way down and still be above the pad.

On my previous set up I had the motor mounted to the plate using the bottom holes putting me up about 2" to start & running the jack plate up 4" put me at 0 with the pad, now I'll mount the motor to it's lowest point & I'm thinking I'll be with the jack plate full down a bit more than an inch below the pad, i'll know more later today

Hayabusa

Well-known member

Sounds like a plan, plenty of time to have Nick install my Foot Throttle I think there's lots of glass cutting involved & I don't want to get itchyGet her done! We're planning a lock park to Clewiston run on sunday the 24th!

kct11

Well-known member

On my previous set up I had the motor mounted to the plate using the bottom holes putting me up about 2" to start & running the jack plate up 4" put me at 0 with the pad, now I'll mount the motor to it's lowest point & I'm thinking I'll be with the jack plate full down a bit more than an inch below the pad, i'll know more later today

Thing about having the motor mounted low on the plate is you run out of room for tilt....at least with a 300xs and hydrulic steering. When I built my new setback I designed almost too much pre-jack in it. I had enough room to change it to work. My problem was if I didn't use the plate to raise the motor I couldn't trim it all the way up with out interference.

Hayabusa

Well-known member

Curious,what is the weight of the 400r?

Tag on the motor says 315 kilos, 695 lbs & I think that's dry.

Hayabusa

Well-known member

Thing about having the motor mounted low on the plate is you run out of room for tilt....at least with a 300xs and hydrulic steering. When I built my new setback I designed almost too much pre-jack in it. I had enough room to change it to work. My problem was if I didn't use the plate to raise the motor I couldn't trim it all the way up with out interference.

The Verado has the steering & hydraulics in the mounting base & it doesn't move with trim & tilt, the pivot pin is above the base & steering assembly so i'm good there, it would be a pain had it been like the 300xs.

Hayabusa

Well-known member

Hear is were i'm at: jack plate full down nose cone 2" below pad, up 2" 0 with pad, jack plate full up nose cone 4" above pad, rough idea with my broom stick

Oh almost forgot, don't know if i mentioned it before, 14" of set back.

Oh almost forgot, don't know if i mentioned it before, 14" of set back.

Attachments

Last edited:

Hayabusa

Well-known member

nastybug

Active member

engine height

Looks great so far. Cant wait to see how far up you can run the propshaft. I just went thru this with my new rig. Skater 318. Used to have a 21 ft pulsate CD. My 400s are mounted to 3 inch jack plates right on the hull. We ended up 2 inches above the bottom and also had water ramps cut in the bottom so we could be that high. Skater didn't want to put Set back in it but I think it needs 10inches or so. You should be able to go pretty high as you have about a foot more setback or so than me. Just watch pressure. Good luck and can't wait to see your results.

Looks great so far. Cant wait to see how far up you can run the propshaft. I just went thru this with my new rig. Skater 318. Used to have a 21 ft pulsate CD. My 400s are mounted to 3 inch jack plates right on the hull. We ended up 2 inches above the bottom and also had water ramps cut in the bottom so we could be that high. Skater didn't want to put Set back in it but I think it needs 10inches or so. You should be able to go pretty high as you have about a foot more setback or so than me. Just watch pressure. Good luck and can't wait to see your results.

JUPITER PULSARE

Well-known member

How is it going?

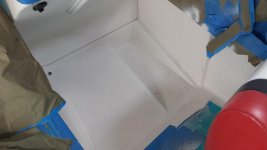

He dropped off the boat at Nick's Creative Marine a few weeks ago to have a Verado Hot Foot installed. They notched out the built in foot rest area of the inner liner to do a custom installation on the hot foot. It turned out awsome!!

He dropped off the boat at Nick's Creative Marine a few weeks ago to have a Verado Hot Foot installed. They notched out the built in foot rest area of the inner liner to do a custom installation on the hot foot. It turned out awsome!!

I was thinking of notching the inner liner of my BRX for a foot throttle as well. Hope he posts pics!!

JUPITER PULSARE

Well-known member

I was thinking of notching the inner liner of my BRX for a foot throttle as well. Hope he posts pics!!

Here you go:

Attachments

Wow, thank you! They did a very nice job of the glass work and I'm glad you had pics because it's not what I was picturing in my head. Won't the foot throttle be too close to the seat that way? From the pics it looks like the foot throttle might have to be mounted back a ways so that the top of it won't hit the vertical kick panel when the pedal is at WOT. Maybe it's just the pics that make it look like that.

JUPITER PULSARE

Well-known member

Wow, thank you! They did a very nice job of the glass work and I'm glad you had pics because it's not what I was picturing in my head. Won't the foot throttle be too close to the seat that way? From the pics it looks like the foot throttle might have to be mounted back a ways so that the top of it won't hit the vertical kick panel when the pedal is at WOT. Maybe it's just the pics that make it look like that.

No, the foot throttle won't interfare with anything. It was carefully planned and measured out. Remember, there are no manual cables..just a plug in harness because the Verados have digital shift/thottles..